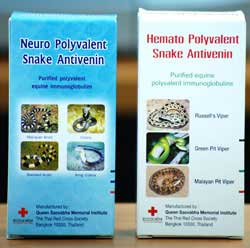

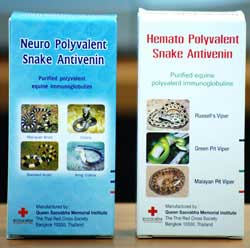

2024 Red Cross Snake Antivenin

FREE WORLDWIDE DELIVERY

Red Cross Antivenin for Green Pit Viper, Malayan Pit Viper, Russell’s Viper, Cobra, King Cobra, Malayan Krait, and Banded Krait snakes.

–

Hemato Polyvalent Snake Antivenom

$199.00

Add to cart

Free: Surprise Gift

$0.00

Add to cart

Neuro Polyvalent Snake Antivenom

$199.00

Add to cart

King Cobra Snake Antivenom

$199.00

Add to cart

Cobra Snake Antivenom

$199.00

Add to cart

Green Pit Viper Snake Antivenom

$199.00

Add to cart

African Snakes Polyvalent Antivenom

$199.00

Add to cart

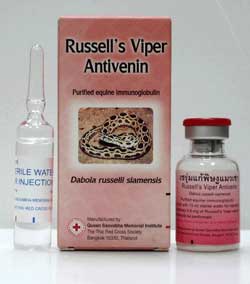

Russell’s Viper Snake Antivenom

$199.00

Add to cart

–

How to produce snake antivenom serum

The official Red Cross snake farm is a world leader in producing various types of serum for snakebite victims in terms of quality and quantity, and is has been supplying for decades many types of snake antivenom to treat bites from snakes as cobra (Monocellate Cobra (Naja kaouthia)), king cobra (Ophiophagus Hannah Snake), banded krait (Bungarus fasciatus Snake), Russell’s viper (Daboia Russelli Siamensis), Malayan pit viper (Calloselasma Rhodostoma), and Green Pit Viper (Trimeresurus Albolabris).

Antiserums are normally prepared from blood plasma from horses immunized by injection of antigen to let the horse’s immune system generate “Immunoglobulin” that has neutralization activity and antigen specificity.

For snake antivenom production the snake venom has to be injected into a horse because after injection the horse will generate immunoglobulin, then its blood will be collected and the hemoglobin will be separated from plasma. This plasma fraction containing the immunoglobulin is used for antivenom production.

The plasma consists of many proteins but only immunoglobulin can neutralize snake venom so useless proteins for venom serum production such as albumin, fibrinogen and others are removed to reduce allergic reaction when injected.

Clear explanation about how is snake antivenom produced by Red cross

– First, snake venom is injected into a horse and the weekly dosage is gradually increased until the horse is able to produce its own natural antivenin. To ensure that the product has the required strength, blood is drawn from the horse and tested at intervals.

– Second, when the antivenin meets the required strength, some blood is drawn from the horse (without causing any harm to the animal) and preserved in a clean, safe container. Then the antivenin is purified thanks to sedimentation and sifting processes so that non-antibody-related proteins which tend to cause allergy when administered to patients are extracted from the compound that is the most efficient against snake venom.

– Third, the serum is bottled and dehydrated to make it easy to transport and store for long periods (up to 5 years).

Snake antivenin is now ready but to ensure the serum’s effectiveness and safety many quality control tests are also conducted on animals under laboratory conditions in compliance with World Health Organization standards to be sure that Red cross antivenom is proper for human use and 100% safe for patients.